Different types of void fill material

Void fill material is used to fill empty spaces or gaps in packaging to provide cushioning, protect items from damage during shipping, and ensure they remain secure within their packaging.

There are many ways to fill up your packages, like: Bubble Wrap, Packing Peanuts, Air Cushions, (Kraft) Paper, Foam Sheets or Cardboard Inserts. Read about the advantages and disadvantages of these types of Void Fill material below. Or get to know Inflatabag™ (nice to meet you).

Bubble Wrap

Bubble wrap is often used for protecting fragile items by wrapping them or placing sheets between items in a package. Void fill bubble wrap, also known simply as bubble wrap, offers several advantages when used as a packaging material. The air-filled bubbles make sure to absorb shocks during your shipment.

Advantages of bubble wrap as void fill

Bubble wrap is cost-effective, and in many cases, bubble wrap can be reused. If recipients take care when unpacking, they can save the bubble wrap for future use, reducing waste and cost. Bubble wrap is generally resistant to moisture, which helps protect items from water damage. It also reduces static.

Disadvantages of bubble wrap as void fill

-

- Limited Reusability – While bubble wrap can be reused in some cases, it is not as durable as some other packaging materials. After multiple uses, the bubbles can lose their air and effectiveness, making the bubble wrap less suitable for cushioning and protection.

- Storage Space – Bubble wrap can take up a significant amount of storage space. This can be a disadvantage for individuals or businesses with limited storage space.

- Not Suitable for All Items – Bubble wrap may not be the best choice for all items. It may not provide adequate protection for extremely delicate or heavy items, and using too much bubble wrap for small items can lead to excessive packaging material waste.

- Electricity – in some cases, the bubbles in bubble wrap can generate static electricity, which may not be suitable for packaging sensitive electronic components or devices.

Packing Peanuts

These are lightweight, foam-based materials that fill voids and cushion items. Packing peanuts (foam peanuts)are effective at preventing movement within a package and absorbing shocks. They are a cost-effective packaging material, often available at a reasonable price.

Advantages of peanuts as void fill

Packing peanuts excel at providing cushioning and shock absorption. They can help protect fragile and delicate items from damage during shipping. It can be used for various types of products, including electronics, glassware, and ceramics. They conform to the shape of items and fill voids effectively. Packing peanuts are generally resistant to moisture, helping to protect items from water damage during transit.

Disadvantages of packing peanuts as void fill

-

- Environmental concerns – One of the most significant drawbacks of packing peanuts is their environmental impact. Most packing peanuts are made from expanded polystyrene (EPS), a type of plastic that can contribute to plastic pollution.

- Messy – Packing peanuts can create a mess when handling or unpacking items. They can easily spill out of packages, and the static charge in some types of packing peanuts can cause them to cling to surfaces.

- Waste and disposal – Disposing of packing peanuts can be a challenge. Recycling facilities may not accept them, and they can take up space in landfills. Some eco-conscious consumers and businesses avoid using them for this reason.

- Volume – Packing peanuts can take up a significant amount of space, especially in storage. They can be bulky and challenging to manage in large quantities.

- Static electricity – Certain types of packing peanuts can generate static electricity, which may not be suitable for packaging sensitive electronic components or devices.

- Weight distribution – If not properly distributed, packing peanuts may settle during shipping, leaving areas of the package less protected.

Air Pillows or Cushioning Bags

Air pillows, like Inflatabag™ are inflatable plastic bags that can be used to fill voids and provide cushioning. They are versatile and can be used for various packing needs. Air cushions, also known as air pillows or airbags, are a popular choice for void fill packaging in various industries.

Advantages of air pillows as void fill

-

- Lightweight – Air cushions are very lightweight, which helps minimize shipping costs. They add very little to the overall weight of the package, reducing shipping expenses, especially for companies that charge based on weight.

- Space-Efficient – When deflated, air cushions take up minimal space. This is advantageous for both storage and transportation, as they can be stored in a compact form and inflated as needed.

- Customizable – Air cushions can be inflated to various sizes to fit different packaging needs. This versatility allows for efficient void fill in packages of different shapes and sizes.

- Cushioning and Protection – Air cushions provide excellent cushioning and protection for fragile or sensitive items. They help prevent movement and reduce the risk of damage during transit.

- Shock Absorption – The air within the cushions can absorb shocks and vibrations, further protecting the packaged items from potential damage during shipping.

- Eco-friendly – Air cushions can be reused or deflated for easy disposal.

- Reduces Product Damage – By providing a protective barrier between items and the walls of a shipping box, air cushions help minimize product damage, which can lead to lower return rates and better customer satisfaction.

Kraft Paper or Paper-Based Void Fill

This is eco-friendly packaging material made from paper. Crumpled kraft paper or paper-based void fill can be used to fill empty spaces and provide padding.

Advantages of paper as void fill:

Paper-based void fill is typically made from recycled or recyclable materials, making it an eco-friendly choice. Paper packaging can be used for various packaging applications, including void fill, wrapping, cushioning, and interleaving. It is suitable for a wide range of products and packaging needs. Paper-based void fill is often more affordable than some other packaging materials, making it an economical choice for businesses looking to reduce packaging costs. It is straightforward to use paper void fill. It can be crumpled, folded, or shredded to fit the voids within packaging boxes. This simplicity can improve packaging efficiency.

Disadvantages of paper as void fill:

-

- Limited Shock Absorption – While paper packaging offers decent cushioning, it may not provide the same level of shock absorption as materials like foam or air cushions. Extremely fragile items may require additional protective measures.

- Less Effective for Heavy Items – Paper-based void fill may not be as effective for cushioning heavy items, as it may compress under the weight of the product, reducing its protective capabilities.

- Messy – Some types of paper void fill can produce dust and debris, which can be messy and require additional cleanup. This can be a concern in clean or sterile environments.

- Limited Moisture Resistance – Paper is susceptible to moisture and may lose its protective qualities if exposed to water or humidity. This can be a concern when shipping items in wet or damp conditions.

- Storage Space – Storing large quantities of paper void fill can require significant storage space, which may be a challenge for some businesses with limited warehouse space.

Foam-In-Place Packaging

Foam-in-place packaging, also known as foam-in-bag or molded foam packaging, involves using a liquid foam that expands and solidifies around a product to provide customized protection. It’s often used for fragile or high-value items.

Advantages of Foam-In-Place Packaging:

Foam-in-place packaging offers a high degree of customization. It molds itself precisely around the product, providing an excellent fit and protection. The foam used in this packaging method provides cushioning and shock absorption. Foam-in-place packaging immobilizes the product inside the box, preventing shifting or damage caused by vibration and impact during shipping. It can be formulated to provide moisture resistance, protecting products from water damage.

Disadvantages of Foam-In-Place Packaging:

-

- Expensive – Foam-in-place packaging can be relatively expensive, both in terms of materials and equipment.

- Space Requirements – The equipment needed for foam-in-place packaging takes up space, which may not be suitable for businesses with limited storage or packaging areas.

- Takes time – Preparing foam-in-place packaging takes time, and the process may slow down the packing operation, especially when dealing with a high volume of shipments.

- Environmental Impact – While foam-in-place packaging can be recycled in some cases, it is not as environmentally friendly as some other packaging materials like paper or air cushions. The production of foam materials can have a more significant environmental footprint.

- Bulkiness – Foam-in-place packaging can add bulk to packages, potentially increasing shipping costs due to dimensional weight charges.

- Chemical Sensitivity – Some products may be sensitive to the chemicals used in the foam-in-place process, so compatibility should be considered.

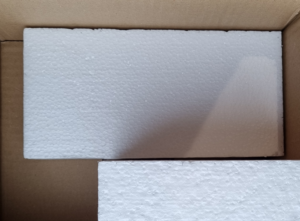

Foam Sheets and Rolls

Foam sheets or rolls can be cut to size and used to wrap items or fill empty spaces in packaging. Foam sheets are a versatile packaging material often used as void fill, providing a protective cushion around products inside a shipping container.

Advantages of Foam Sheets as Void Fill:

Foam sheets can be used for various packaging applications, including wrapping, interleaving, and creating custom-shaped cushions. They can be easily cut or shaped to fit the specific needs of the product being shipped. Foam sheets can often be reused multiple times and provide a degree of protection against moisture and humidity, helping to prevent damage to sensitive items. Unlike some other void fill materials like loose packing peanuts, foam sheets do not generate dust or debris that can be messy or require additional cleanup.

Disadvantages of Foam Sheets as Void Fill:

-

- Expensive – High-quality foam sheets can be relatively expensive, particularly when compared to some other void fill options like packing paper or air cushions.

- Bulkiness – Foam sheets can be bulky, which can increase shipping costs due to dimensional weight charges if they add significant size to the package.

- Limited Environmental Friendliness – While foam sheets can be reusable, they are not biodegradable or easily recyclable, which may be a concern for businesses looking for more environmentally friendly packaging options.

- Storage Space – Storing large quantities of foam sheets can require substantial storage space, which may be challenging for businesses with limited warehouse space.

- Manual Labor – Shaping and cutting foam sheets to fit specific packaging needs can be time-consuming and may require manual labor, potentially slowing down the packaging process for high-volume operations.

Corrugated Inserts or Dividers

Corrugated cardboard inserts can be customized to fit the shape of the product and keep it in place within a box. They are commonly used for electronics and glassware.

Advantages of Corrugated Inserts as Void Fill:

Corrugated inserts can be designed and cut to precise specifications to provide tailored protection for the products they separate. This customization ensures that each item is securely held in place. Corrugated inserts can be used to create multiple layers within a box, allowing for efficient use of space and organization of items. This is particularly useful when shipping multiple products with different shapes and sizes in a single container. In addition to protecting products from external forces, corrugated inserts can provide structural support to the shipping container itself, helping prevent crushing or deformation during transit. Corrugated inserts are lightweight, which can help reduce shipping costs, especially when combined with lightweight products.

Disadvantages of Corrugated Inserts as Void Fill:

-

- Limited Cushioning – While corrugated inserts are excellent at providing separation and organization, they offer limited cushioning and shock absorption compared to materials like foam or air cushions. Additional cushioning may be needed for fragile items.

- Space Occupancy – Corrugated inserts can take up significant space inside the shipping container, potentially reducing the available space for products or increasing shipping costs due to dimensional weight charges.

- Assembly Required – Preparing and assembling corrugated inserts can be time-consuming, especially for large quantities or complex packaging configurations. This can slow down the packaging process.

- Single-Use – Unlike some other packaging materials like air cushions or foam sheets that can be reused or repurposed, corrugated inserts are typically single-use and may need to be discarded after one use.

- Environmental Impact – While corrugated inserts are recyclable, their production can still have an environmental impact. Businesses concerned about sustainability may seek more eco-friendly packaging alternatives.

- Not Suitable for All Products – Corrugated inserts are best suited for products with defined shapes and sizes. Irregularly shaped or extremely delicate items may require a different packaging solution.

The choice of void fill material depends on the nature of the items being shipped, their fragility, cost considerations, and environmental preferences. It’s important to select the most appropriate void fill material to ensure that your products reach their destination safely and in good condition.